|

|

Note: The 40 direct mount crown requires a total stack height range from 105 mm to 166.8 mm.

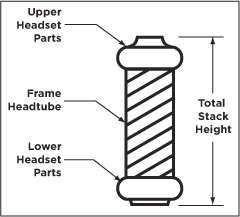

See Figure 1: 40 Headset Stack Height to understand what defines total stack height. Measure to verify whether your total stack height falls within this height range specification.

Note: If you're installing a steerer tube-mounted stem, the total height of spacers used on a FOX steerer tube should never exceed 30 mm.

Figure 1: 40 Headset Stack Height

WARNING: Have a qualified bicycle mechanic install the 40. Improperly installed forks are dangerous, which can cause loss of steering control that can lead to SERIOUS INJURY OR DEATH.

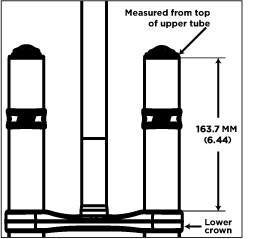

The 40 with a direct mount upper crown is assembled with the lower crown set to 163.7 mm below the top of the upper tubes (see Figure 2: 40 Crown Height). The lower crown position is set to allow 6 mm clearance between the bottom of the crown and the top of a 2.80" tire when bottomed out. Do not change the position of the lower crown.

WARNING: If the steerer has any nicks or gouges, the crown/steerer assembly must be replaced. A nick or gouge can cause the steerer to fail prematurely, which can cause loss of control of the bicycle resulting in SERIOUS INJURY OR DEATH.

Note: The FOX 40 can be set up with either a direct-mount or a steerer mounted stem.

CAUTION: Fox Racing Shox does not manufacture a direct mount stem. Be sure to refer to your stem manufacturer's installation instructions. Measure at least twice to be certain of all measurements, before cutting the fork steerer!

WARNING: Do not cut the steerer more than three (3) mm below the uppermost installed part. If the steerer length is mistakenly cut too short, it MUST BE REPLACED! Using a fork with clamped steerer engagement that is too short can lead to sudden fork failure, which can cause irrecoverable loss of control of the bicycle resulting in SERIOUS INJURY OR DEATH.

Figure 3: Star-fangled Nut Installation Depth

Note: It is important that the Direct Mount stem stays loose (NOT torque-tightened) or uninstalled, to allow proper adjustment of the headset.

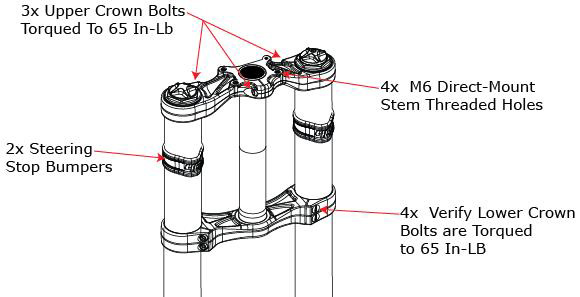

Figure 4: 40 Upper Crown Installation

WARNING: Do not over-tighten the pinch bolts. Too much torque can damage the bolts, fracture the crown, or damage the threads. Any of these could cause fork failure leading to loss of control, resulting with SERIOUS INJURY OR DEATH.

Note: The 40 will accept tire sizes up to 2.80 inches wide. Any tire larger than 26 x 2.60 must be checked for clearance.

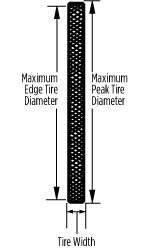

With the tire installed and inflated on the rim, measure the following three dimensions:

Maximum Peak Tire Diameter = 694 mm = 27.3 inch

Maximum Edge Tire Diameter = 670 mm = 26.41 inch

Maximum Tire Width = 71 mm = 2.80 inch

Figure 5: Proper Tire Diameter

WARNING: Do not use a tire if any measurement exceeds the maximum dimensions shown above. Using larger tires is not recommended and can cause SERIOUS INJURY OR DEATH.

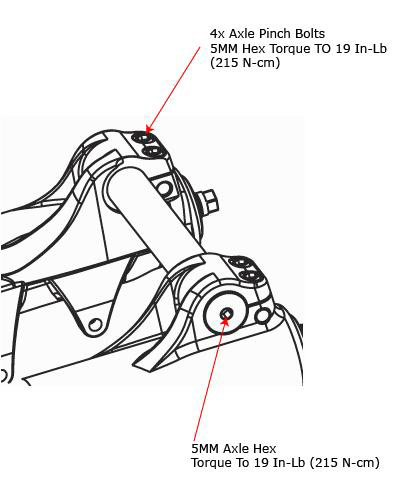

Refer to Figure 6: 40 Axle Clamps for the following procedure:

If installing a Steerer Mounted stem: tighten the steerer pinch bolts on the stem, according to the stem manufacturer's instructions.

Figure 7: 40 Upper Crown International 4-Bolt Pattern (Specification)

The 40 is designed only for use with DH disc brakes with disc rotor sizes of 200 – 225 mm. The 40 can use DH mechanical or hydraulic disc brake systems.

WARNING: Never modify the lower leg or use cantilever rim brakes, as this could lead to SERIOUS INJURY OR DEATH.

The 40 disc bolt pattern uses:

|

Figure 8: 40 Brake Hose Guide Installation

|

Figure 9: 40 Disc Brake Hose Guide Routing

|

![]()

Bushing Technology & Inspection | Seals & Foam Rings | Control Direction | Oil Volumes | Structural Inspection | Dropout Thickness Inspection | Torque Values | Unit Conversion | Suspension Tuning Tips | Using the Pump | Important Safety Information | Service Intervals | Contact FOX Service | Warranty Information | FOXHelp Service Web Site

Copyright © 2010

FOX Factory Inc.