36 VAN RC2 & R

Installing Your Fork | Before You Ride | Setting Sag | Adjusting Rebound | Adjusting High-Speed Compression | Adjusting Low-Speed Compression | Changing the Coil Spring | Service Intervals | Important Safety Information

|

weight RC2 |

5.53 lbs./2.51 kg | |

|

travel The total amount the shock or fork compresses. On a shock it is measured using the eye-to-eye distance or shaft travel. |

6.3 in. / 160 mm | |

|

features/adjustments RC2 |

low-speed compression, high-speed compression, hydraulic bottom-out in damper, coil spring preload Initial force placed on an air or coil spring., rebound | |

|

features/adjustments R |

hydraulic bottom-out in damper, coil spring preload, rebound | |

|

spring/damper type |

steel spring/RC2 FIT damper | |

|

intended use |

downhill A style of riding defined by steep descents down insanely steep mountains, hills or, in some cases, buildings. Downhill bicycles and their components are generally the strongest available. Hence, the 40 and DHX 5.0., all-mountain A style of bicycle riding that melds the stamina and conditioning required of cross-country with the technical abilities of freeriding., freeride A style of riding that is defined by short course technical acrobatics and athletes that defy gravity. Generally, the bikes and components required for freeriding are stronger and heavier than their lightweight cross-country brethren. Combine the aerial pyrotechnics of freeriding with some longer trails and courses, as is typical of cross-country riding, and now you're looking at all-mountain riding. | |

|

color |

Black Diamond |

Be sure your fork is properly installed before proceeding. Clicking on the link above will take you to a new page.

Check that the 20mm axle pinch bolts and crown pinch bolts are properly adjusted and tightened.

Clean the outside of your fork with soap and water and wipe dry with a soft dry rag. Do not spray water directly on the seal/upper tube junction. Do not use a high pressure washer on your fork.

Inspect entire exterior of fork for damage. The fork should not be used if any of the exterior parts appear to be damaged. Please contact your local dealer or FOX Racing Shox for further inspection and repair.

Check headset adjustment. If loose, adjust according to manufacturer’s recommendations.

Check that brake cables or hoses are properly fastened.

Check that the front and rear brakes operate properly on flat land.

You can also view a Flash video on Setting Sag.

To get the best performance from your fork, it is necessary to set and adjust sag Amount a shock or fork compresses with the rider sitting on the bike in a normal riding position. Best measured with an assistant holding your bike up and with the rider in full riding gear. On a fork, it is helpful to place a ZIP tie around one of the upper tubes.. Generally, sag should be set to 15 – 25% of total fork travel.

Install a zip tie with light friction on the upper tube and push it down until it contacts the fork seal.

Carefully sit on the bike and assume a normal riding position. The fork should compress slightly.

Being careful not to further compress the fork, dismount the bicycle. Measure the distance between the seal and the zip tie. This distance is sag.

Compare your sag measurement

to the Sag Setup table below.

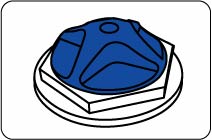

If sag is lower than in the table, turn the preload knob (shown

below) counter-clockwise one (1) full turn. Measure sag again and repeat

adjustment if necessary.

If sag is higher than in the table, turn the preload knob clockwise A motion that proceeds from the top to the right, then down and then

to the left, and back to the top, like the clock's hands.

one (1) full turn. Measure sag again and repeat adjustment if necessary.

If correct sag cannot be achieved by adjusting the preload knob, see the

36 VAN Coil Spring Settings table

below. You may need to change

to a coil spring with a different spring rate Force required to compress a spring one inch..

|

FOX Part # |

Spring Rate |

Color Code |

Travel Range |

Rider Weight |

|

039-05-050 |

35 lb/in |

Black |

160 |

<90–115 |

|

039-05-051 |

40 lb/in |

Purple |

160 |

115–155 |

|

039-05-052 |

45 lb/in |

Blue |

160 |

150–180 |

|

039-05-053 |

50 lb/in |

Green |

160 |

175–210 |

|

039-05-054 |

55 lb/in |

Yellow |

160 |

205–240+ |

|

Symptom |

Remedy |

|

Too much sag |

Change to higher rate coil spring |

|

Too little sag |

Change to lower rate coil spring |

|

Excessive bottoming |

Change to higher rate coil spring |

|

Harsh ride; full travel not utilized |

Change to lower rate coil spring |

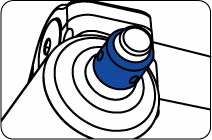

The rebound knob (shown below) is located on the top of the right fork leg, and has 15 clicks of adjustment. Rebound controls the speed at which the fork extends after compressing. Turning the knob clockwise slows down rebound; turning the knob counterclockwise speeds up rebound. As a starting point, turn the rebound adjuster knob all the way clockwise (full in) until it stops, then turn counterclockwise (out) 8 clicks.

|

Knob Setting |

Setting Description |

Tuning Tips |

Setup Tips |

|

|

Slow Rebound |

Too slow and your fork will pack down and ride harsh. |

If you increase your spring rate or air pressure, you will need to slow down your rebound |

|

8 (Factory setting) |

Average Rebound |

||

|

|

Fast Rebound |

Too fast and you will experience poor traction and wheel hop. |

If you decrease your spring rate or air pressure, you will need to speed up your rebound setting. |

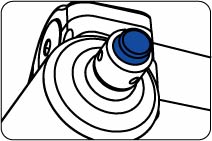

High-speed compression damping Oil or air damping resistance felt when trying to compress a shock or fork. controls the force it takes to move the fork through its travel and how the wheel reacts to a bump. This adjuster rotates to stops at each end and has 15 clicks of adjustment. It is preset from the factory at 1 click in from the full out (counterclockwise) position. The knob is protected by the black protective cap. Never ride your FOX 36 without the black protective cap.

|

Knob Setting |

Setting Description |

Tuning Tips |

|

|

Slow Compression |

Maximum wheel traction and bump compliance. If setting is too soft, you may bottom often on square-edged hits and G-outs. |

|

1 (Factory setting) |

Average Compression |

|

|

|

Firm Compression |

Reduces bottom-out and provides maximum bump absorption. If setting is too firm, you may experience a harsh ride with bad traction and use too little available travel. |

The high-speed compression adjuster is equipped with a maximum “Boost” setting. This setting offers increased bump force resistance well beyond the adjuster's linear range up until the stop at full firm (clockwise). To enable the “Boost” feature, turn the high-speed compression knob to the full in (clockwise) position, to the stop with firm hand torque. You can use a 3mm hex key to assist in turning the knob to the full in position or to untorque when de-tuning the Boost feature.

Low-speed compression damping controls the influence of the rider’s weight shifts and bike attitude under braking. This adjuster rotates to stops at each end and has 17 clicks of adjustment. It is preset from the factory at 1 click in from the full out (counterclockwise) position. The knob is protected by the black protective cap. Never ride your FOX 36 without the black protective cap.

|

Knob Setting |

Setting Description |

Tuning Tips |

|

|

Slow Compression |

Maximum wheel traction and bump compliance. Too soft and you maybe have excessive brake dive and wallowy feel. |

|

1 (Factory setting) |

Average Compression |

|

|

|

Firm Compression |

Resists brake dive and keeps the fork up in the travel. Too firm and you may have poor traction in loose conditions. |

The 36 VAN is equipped with a patent-pending Internally Adjustable Hydraulic Bottom-Out Control System. This feature can be adjusted inside the cartridge by FOX Racing Shox or an Authorized Service Center. It comes preset from the factory at the FIRM setting.

With a 32mm 6-point socket wrench, loosen and remove the preload topcap (top of left leg).

Compress the fork slightly and remove the coil spring. You may need to firmly pull up on the spring to disengage it from the plunger shaft.

Wipe the spring dry with a rag and check its color code.

Install the new spring by dropping it into the upper tube, then torque the top cap to 165 in-lbs (1864 N-cm).

Rotate the fork to a horizontal position and shake it. This lubricates the spring before its first push into travel.

Measure and set sag.

eng041